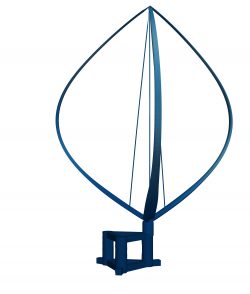

Brandon Ennis, Offshore Wind Technology Lead at Sandia National Laboratories, has a radically new idea for offshore wind turbines. Instead of a tall, unwieldy tower with blades on top, he imagined a towerless turbine with blades pulled like a bow.

Brandon Ennis, Offshore Wind Technology Lead at Sandia National Laboratories, has a radically new idea for offshore wind turbines. Instead of a tall, unwieldy tower with blades on top, he imagined a towerless turbine with blades pulled like a bow.

Innovative design for offshore wind farms from Sandia National Laboratories: No heavy towers, instead wind blades taut with guy wires. (Illustration by Brent Haglund) Click on the thumbnail for a higher resolution image.

This design allows giant generators that produce electricity from rotating blades to be placed near the water instead of on top of a 500-foot tower. This makes the top of the turbine less heavy, reducing the size and cost of the floating platform required to stay afloat. Sandia filed a patent for this design in 2020.

But before he can put his ideas into action, the team needs to build software that can model the turbine and floating platform’s response to different wind and sea conditions in order to determine the best overall system design. had.

Now the Sandia team has a functional design tool, or “drawing board,” to start designing and optimizing lighter floating wind turbine systems.

“To design our floating wind turbine system, we needed a design tool that could simulate wind, waves, blade elasticity, platform movement and controllers,” said Ennis. “There are some tools out there that can do some of what you need to do without needing all of the two-way coupled dynamics needed to design and optimize this kind of wind turbine. It was a big undertaking, but essential.” Without such a reliable tool, the floating vertical axis wind turbine industry cannot exist.”

Lighter and cheaper turbines for offshore wind farms

Many offshore winds in the United States blow at depths in excess of 200 feet. At these depths it is very expensive to build the rigid support structures typically used in wind turbines. But subsea-floating wind turbines could play a key role in diversifying renewable energy sources and improving grid stability as cities and states move closer to achieving net-zero emissions targets. said Ryan Coe. Mechanical engineer for Sandia’s Hydraulic Group.

“The high demand for electricity on the coast is one of the reasons offshore wind seems attractive. there’s no such thing,” says Coe. “Also, offshore wind provides power at different times of day than solar and onshore wind.”

Historic photo of Sandia National Laboratories’ experimental 34-meter-diameter vertical-axis wind turbine built in Texas in the 1980s. (Image courtesy of Sandia National Laboratories) Click on thumbnails to see high resolution images.

But floating offshore wind has its own set of challenges, Ennis added. Primarily, it is very expensive to support wind turbines and maintain them when they are out at sea. The goal of the DOE Advanced Research Projects Agency Energy Program is to optimize the design of floating wind turbines, platforms and control systems to maximize output while minimizing costs.

“The question for us is how do we remove mass and cost from the system while maximizing energy recovery. This has led to an innovative towerless vertical axis design,” says Ennis. said.

Most wind turbines today have a horizontal shaft that cranks the generator behind the blades inside the turbine’s nacelle, a box at the top of the turbine that contains the rotor and other critical components, a box at the top of the turbine. It is based around a tall tower with three blades that rotate. But that’s not the only way to design a wind turbine, Ennis said. Some turbines have two or more blades supported by a vertical shaft with a generator under the blades. The design, called the Darrieus Vertical Axis Wind Turbine, has a lower center of gravity and is lighter than traditional wind turbines, says Ennis, but one of his main challenges is keeping the turbine out of extreme winds. It is difficult to protect.

In a traditional horizontal-axis wind turbine, the blades can rotate away from the wind, which can be severely damaging, but Darius’ design catches wind from all directions. Sandia’s design replaces the central vertical tower with taut guy lines, Ennis said. These wires can be shortened or lengthened to adjust to changing wind conditions, maximizing energy capture while controlling strain. Additionally, replacing the shaft with wire further reduces the weight of the turbine, allowing the floating he platform to be even smaller and cheaper.

Design tool development and validation

Image of the team’s new design tool analysis of Sandia National Laboratories’ innovative floating vertical axis wind turbine. (Image by Kevin Moore) Click on the thumbnail for a higher resolution image.

Kevin Moore, Mechanical Engineer in Sandia’s Wind Power Group, and the rest of the team developed a vertical axis wind turbine design tool based on previous work by Sandia Engineer Brian Owens. Coe and Michael Devin, another mechanical engineer in the wind farm group, also worked on it. While the team worked on integrating the physics algorithms, they also improved the accuracy and speed of the algorithms.

Moore also led an effort to validate design tools using data from a 34-meter-diameter ground-mounted vertical-axis wind turbine built by Sandia in the 1980s.

“It was amazing to see the design quality and innovation of the traditional designers while working on the validation work,” says Moore. “It is a privilege to stand on the shoulders of giants while leveraging the latest computing resources.”

According to Ennis, one of the reasons the Sandia team is validating design tools is so that they can ultimately be used to bring vertical-axis wind turbine designs into compliance with appropriate design criteria.

“Today, when companies want to certify their vertical axis wind turbines, there is a lot of uncertainty in the process due to the lack of reliable design tools,” said Ennis. “Our ability to provide reliable design tools means certification bodies are more proactive in approving vertical axis wind turbine designs needed for funding and eventual deployment.”

Spinning up optimized turbine designs

The team can now begin designing a floating vertical axis wind turbine system. According to Ennis, the design tool can be used to model and optimize any vertical axis wind turbine, whether it uses traditional towers or taut guy lines. The team uses a process called control co-design to find the most cost-effective design and control of floating vertical axis wind turbine systems.

“We are simultaneously designing the entire system, the turbine and platform, and their controls to reduce not only the cost of the turbine itself, but the cost of energy equalization,” said Ennis. “Usually one company designs the turbine, another company designs the floating platform of that fixed turbine design, and then another company puts it together with other systems to create an offshore wind farm. You get what you get in the end in terms of cost.”

Ennis said the team hopes to optimize the design of the floating vertical-axis wind turbine system by the end of the year, but the project wouldn’t have been possible without their new specialized software.

“It’s a great tool in terms of how it integrates all of these different functions,” said Coe. “We have linked tools developed to model the aerodynamics and structural dynamics of vertical axis wind turbines, an area in which Sandia has always led, and combined them with fluid dynamics to make them better suited for design optimization. I was able to do.”

Development of the offshore wind turbine design software and future work on optimizing the overall system design is supported by the Energy’s ATLANTIS program, the Department of Energy’s Advanced Research Projects Agency. The Sandia team is working on the project in collaboration with project partners FPS Engineering & Technology and the US Bureau of Shipping.

Sandia National Laboratories is a multi-mission laboratory operated by National Technology and Engineering Solutions of Sandia LLC, a wholly owned subsidiary of Honeywell International Inc., for the National Nuclear Security Administration of the U.S. Department of Energy. With major facilities in Albuquerque, New Mexico and Livermore, California, Sandia Labs has major research and development responsibilities in nuclear deterrence, global security, defense, energy technology, and economic competitiveness.